Unleash Your Inner Shipwright: High-Quality Wooden Boat Kits for Effortless Assembly

The allure of a handcrafted wooden boat is undeniable. Imagine gliding across calm waters in a vessel you built yourself, the scent of freshly varnished wood filling the air. For many, this dream seems out of reach, requiring years of experience and specialized skills. But what if we told you that you could achieve this rewarding experience with surprisingly little effort? High-quality wooden boat kits are revolutionizing boat building, offering detailed instructions and pre-cut components that significantly simplify the process. This means you can enjoy the satisfaction of creating your own stunning boat, regardless of your prior woodworking experience. These kits aren't just about ease of assembly; they also provide access to superior materials and classic designs, ensuring a beautiful and durable final product.

Choosing the Right Kit: Size, Style, and Skill Level

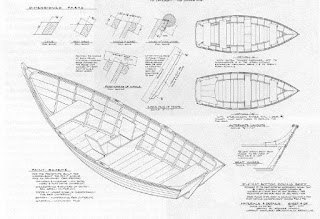

The sheer variety of available wooden boat kits can be overwhelming. To help you navigate this exciting world, consider these key factors: size, style, and your own skill level. Beginners might find smaller kits, like those for kayaks or dinghies, easier to manage. These projects offer a satisfying introduction to boat building techniques without being overly demanding. Intermediate builders can tackle larger rowboats or small sailboats, while experienced craftspeople might venture into more ambitious projects, such as classic designs or those with intricate detailing. Consider your available workspace and time commitment before making your choice. Researching different kit manufacturers and reading reviews will also help you choose a kit that matches your expectations for quality and ease of assembly.

Size Matters: From Kayaks to Classic Sailboats

The size of the boat directly impacts the complexity of the assembly. Small kits, like those for kayaks or canoes, often come with pre-shaped components and straightforward instructions, making them perfect for beginners. Larger kits, such as those for rowboats or small sailboats, require more time and attention to detail, but the reward of a larger, more capable vessel is substantial. Carefully examine the specifications and consider the space required for both the construction process and the final storage of your completed boat.

Style and Aesthetics: Finding Your Perfect Match

Wooden boat kits offer a diverse range of styles, from sleek and modern designs to classic clinker-built models. Consider the aesthetic you prefer and choose a kit that reflects your personal taste. Examine photos and videos of completed kits to get a sense of the final look and feel of the boat. Many kits also allow for personalization, enabling you to add your own unique touches and embellishments after assembly.

The Assembly Process: Step-by-Step Guidance and Support

High-quality wooden boat kits stand apart due to their comprehensive instructions. These guides typically provide detailed, step-by-step instructions, often accompanied by clear diagrams and photographs. Many manufacturers offer additional support resources, including online forums and customer service assistance, to address any questions or concerns you might encounter during the assembly process. This support network can be invaluable, especially for beginners. Don't hesitate to reach out for help – the goal is to enjoy the building process, and expert guidance can significantly enhance your experience.

Essential Tools and Materials: Ensuring a Smooth Build

While most kits provide a list of necessary tools, careful planning is crucial. Before you begin, ensure you have all the tools and materials required for a smooth assembly. This might include basic woodworking tools like saws, clamps, drills, and sandpaper, along with specialized tools depending on the kit. Always check the manufacturer's instructions for a complete list of necessary tools and materials, as some might require specialized glues or fasteners.

Beyond Assembly: Finishing and Personalization

Once the boat is assembled, the real fun begins! Many kits require finishing touches, such as sanding, varnishing, and painting. These final steps not only protect the wood but also allow for personalization. Consider adding custom details, such as brass fittings or decorative accents, to make your boat truly unique. This final step transforms a kit into a cherished, personalized creation, a testament to your skill and dedication.

Investing in Quality: Why Choose a Premium Wooden Boat Kit?

Choosing a high-quality wooden boat kit ensures a rewarding and enjoyable experience. Premium kits use superior materials, resulting in a stronger, more durable boat. Precise pre-cutting and clear instructions minimize frustration and maximize enjoyment. The investment in a quality kit pays off in a beautiful, lasting vessel you'll be proud to own and use for years to come. Remember, selecting a kit that matches your skill level and desired outcome is key to a successful project.